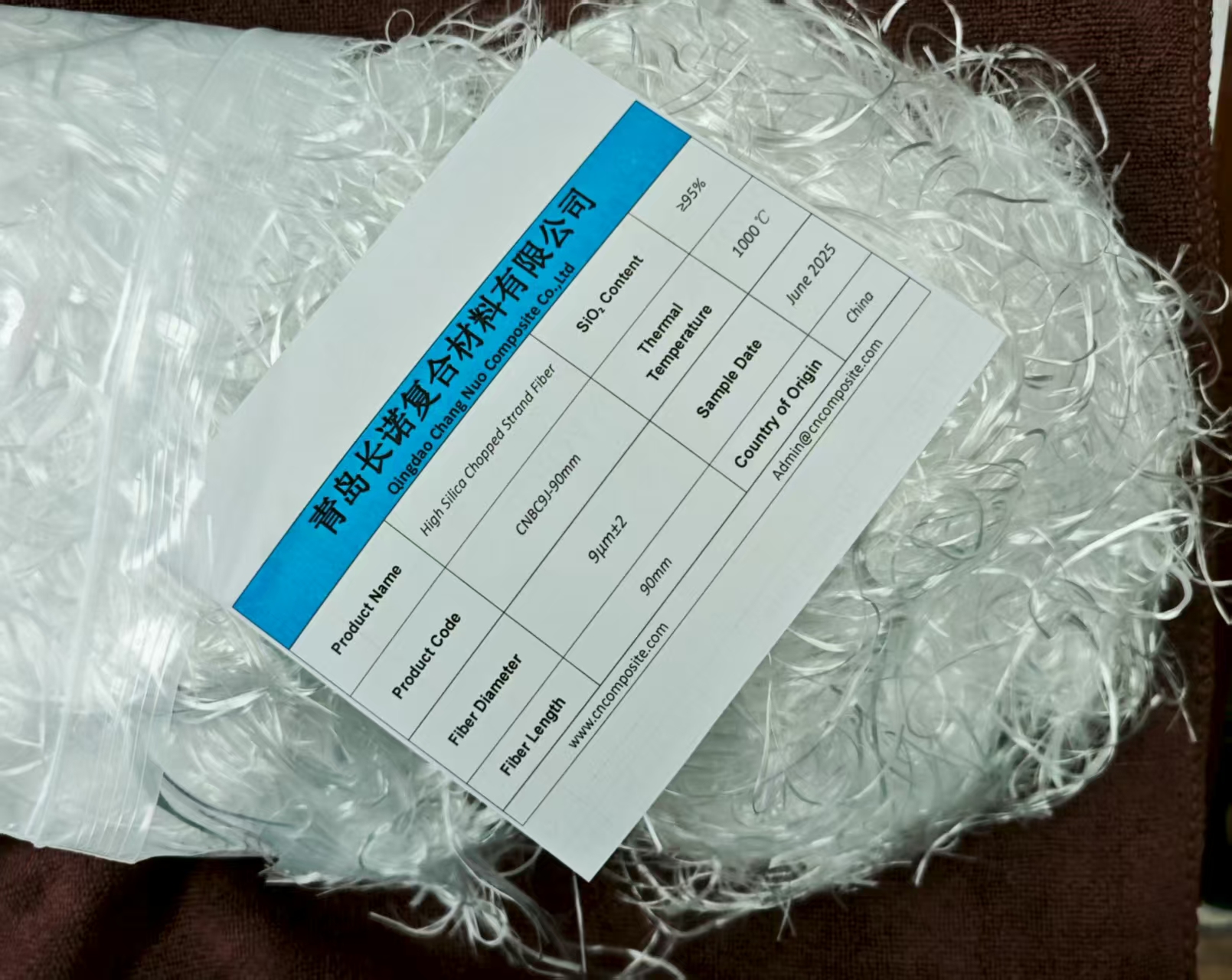

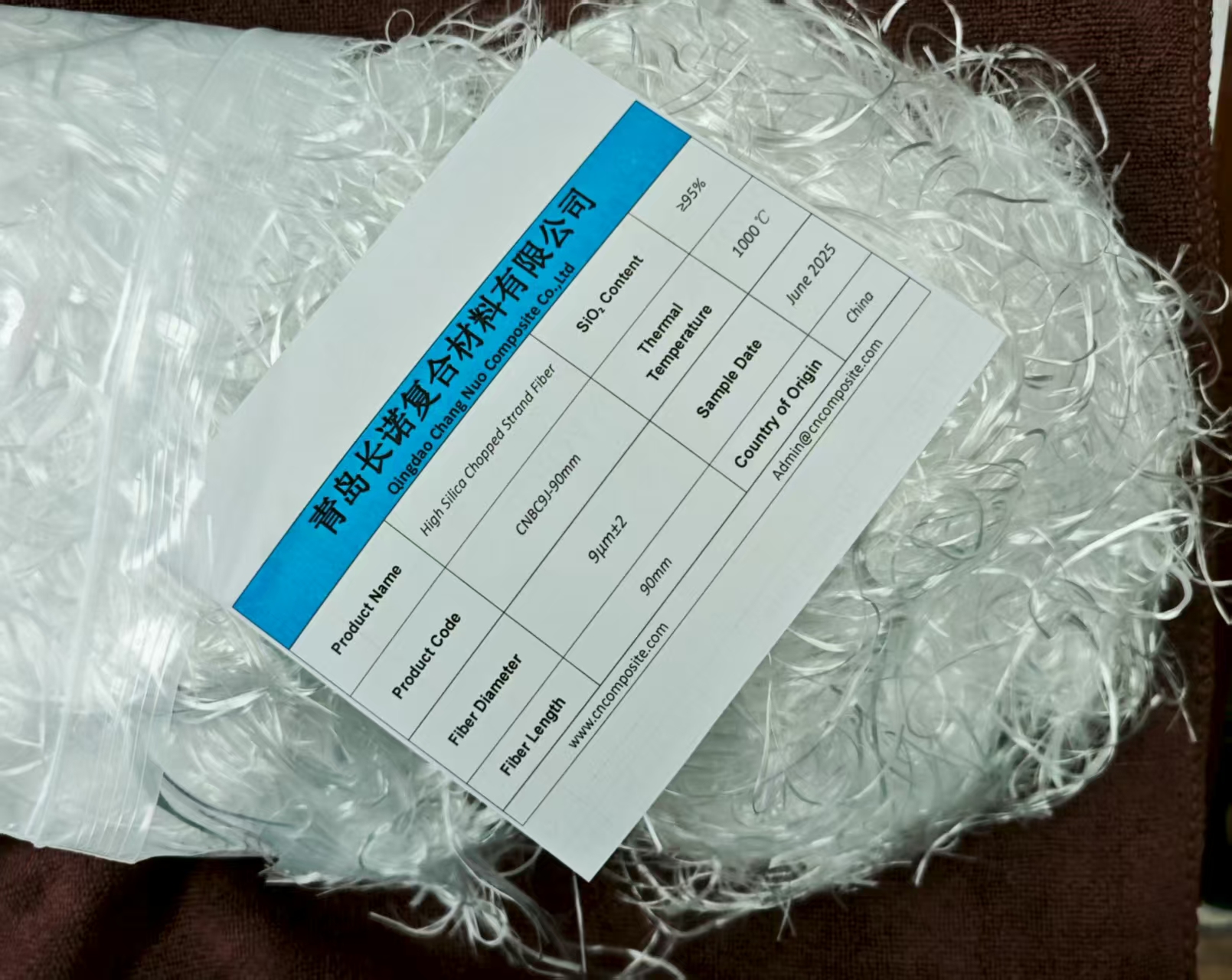

HIGH SILICA CHOPPED STRAND FIBER

High-silica chopped glass fiber strands are made from continuous silica fibers with a diameter of approximately 7-9 μm, which have been specially treated to achieve a SiO2 content exceeding 95%, or a SiO2 + Fe2O3 ratio exceeding 97%. They are primarily used in the production of high-silica needle-punched felt, which serves as a filter material and heat-resistant filling material. They are an ideal alternative to ceramic fibers in thermal insulation applications such as engine protection. They can also be used to reinforce phenolic resins to create ablation-resistant materials.

PRODUCT FEATURES

- Low heat conduction rate;

- Good electrical insulation;

-Excellent chemical stability;

-Soften point around 1700 degree centigrade;

-Long time use under 1000 degree centigrade;

- Non-asbestos and non-pollution.

SPECIFICATION

Product Code:CNBC9L-60/90

|

Indicators/functional |

Value |

|

SiO₂ |

≥94.2% |

|

Al₂O₃ |

3.3% |

|

Fiber Diameter |

9μm±1.5 |

|

Fiber Length |

60/90mm |

|

Moisture Content |

≤3% |

|

Loss on Ignition(%) |

≤5% |

|

Thermal Temperature |

1000℃ |

Notes: Fiber Length could be customized.

Product Code:CNBC9J-60/90

|

Indicators/functional |

Normal Value |

|

SiO₂ |

≥95% |

|

Al₂O₃ |

2.3% |

|

Fiber Diameter |

9μm±2 |

|

Fiber Length |

60/90mm |

|

Moisture Content |

≤4% |

|

Loss on Ignition(%) |

≤10% |

|

Thermal Temperature |

1000℃ |

Notes: Fiber Length could be customized.

APPLICATIONS

High Silica Glass Fiber Chopped Strand is the raw material for High Silica Needle Mat. High Silica Glass Fiber Chopped Strand with heat treatment can be used as filling materials with High Temperature Resistance, High Insulation and Low shrinkage. Its final products are used for the High Temperature-Resistance Insulation materials, High Temperature-Proof materials, High Temperature Gas, Liquid-Filtration materials, Thermal Insulation of Spacecrafts and so on.

STORAGE

High Silica Glass Fiber Chopped Strand should be stored in its original packing in a dry and cool place. Best temperature conditions are from 15-35℃ and humidity between 35%- 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than two layers high, when the pallets are stacked in 2layer, care should be taken to correctly and smoothly move the top pallet.